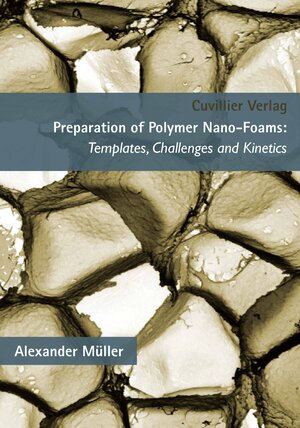

The current energy debate considerably affects science, economy and politics. A key aspect of this discussion is energy saving by improvement of thermal insulations for buildings. In this regard, nano insulation materials (NIMs) are the insulation materials of the future. If additionally, a pore size reduction to nanoscale results in optical transparency, completely new markets for polymer foams will arise. However, the realization of these high-potential materials is accompanied by many challenges, as for example the extremely high interfacial tension emerging during foaming processes that cause an undesired coarsening of the foam structure. To overcome these challenges, new strategies and templates have to be scientifically developed. Moreover, it is crucial to understand the foaming in detail. In this context the early state of foaming was studied by means of the principle of supercritical microemulsion expansion (POSME). The benefit of using microemulsions containing a super- or near-critical fluid as oil component is the thermodynamic stability at high pressures. This allows a fast repeatability of the expansion process at nanoscale by applying pressure cycles. In combination with a specially designed stroboscopic high pressure cell, the structural processes could be observed by time resolved small angle neutron scattering experiments. It turned out that the addition of a low molecular oil as anti aging agent results in a deceleration of foam coarsening during expansion by more than an order of magnitude. Parallel to these studies, the nanofoams by continuity inversion of dispersions (NF-CID) principle was utilized for the preparation of nanoporous polymeric materials. The significant innovation of the NF-CID principle is the generation of an extremely high number density of propellant pools by a continuity inversion of a CO2-soaked colloidal crystal, i. e. the formerly discrete polymer nanoparticles convert into a homogeneous matrix with nanodisperse fluid inclusions, if the temperature is raised above the glass transition of the respective polymer. Expanding those templates by applying a specific set of parameters led to polymethylmethacrylate and polystyrene nanoporous materials that feature pore sizes smaller than 100 nm.

Preparation of Polymer Nano-Foams von Alexander Müller | Templates, Challenges and Kinetics | ISBN 9783954045662